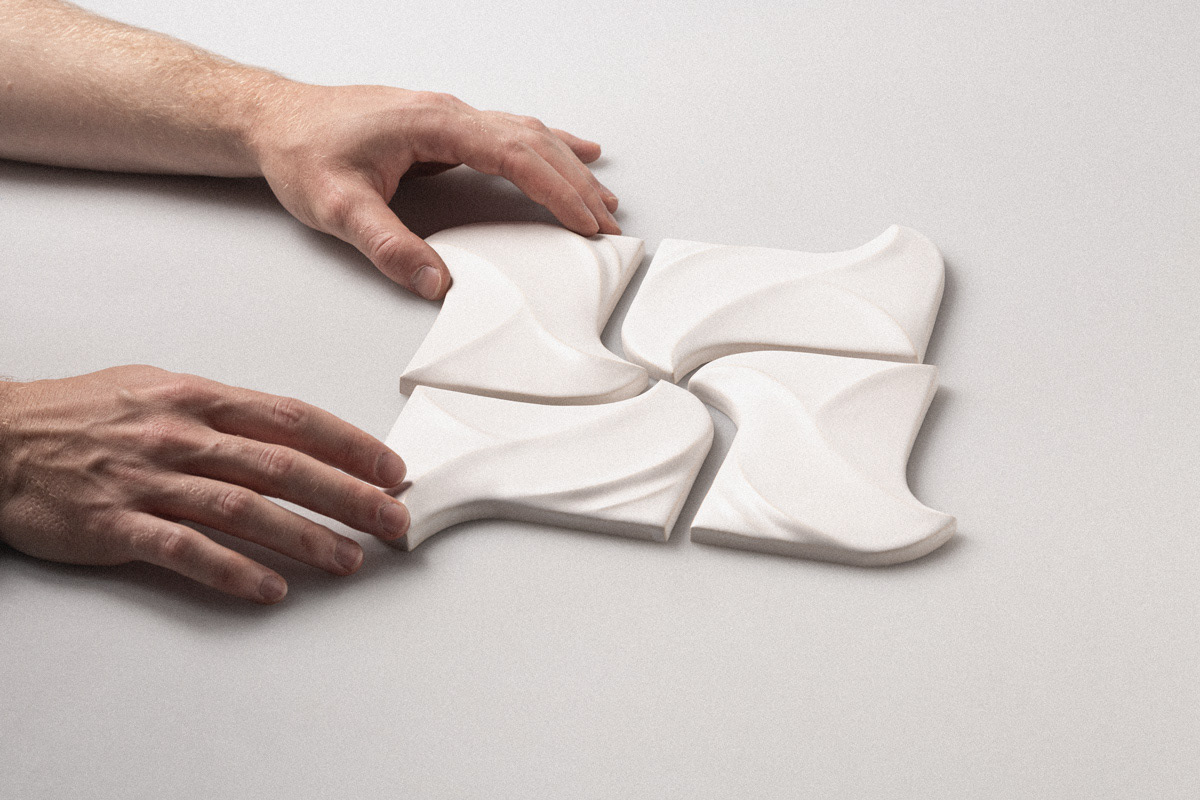

Imagine the essence of flowing water, the serene sounds of the sea, and the tranquil hue of sea foam embodied in one object: the wave. With its natural ceramic color, this tile infuses warmth and relaxation into any space, blending elegance with modernity.

Introducing "l'onda", my modular ceramic tile designed to elevate any wall. Its versatile placement options allow for captivating patterns and shapes, igniting creativity.

Handcrafted with care, each tile undergoes a meticulous process-from plaster model to glazing and firing-resulting in a distinct individuality. Experimenting with different laying directions creates dynamic patterns, transforming walls into captivating works of art.

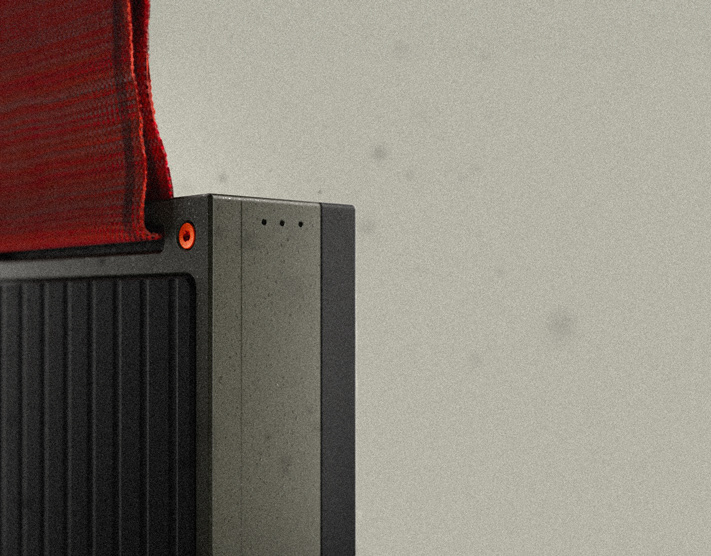

final tile

process

01 Sketches

After a series of simple and swift sketches, I arrived at my final design relatively quickly. Among the various iterations, the design located in the last row, positioned on the right-hand side, emerged as the standout choice.

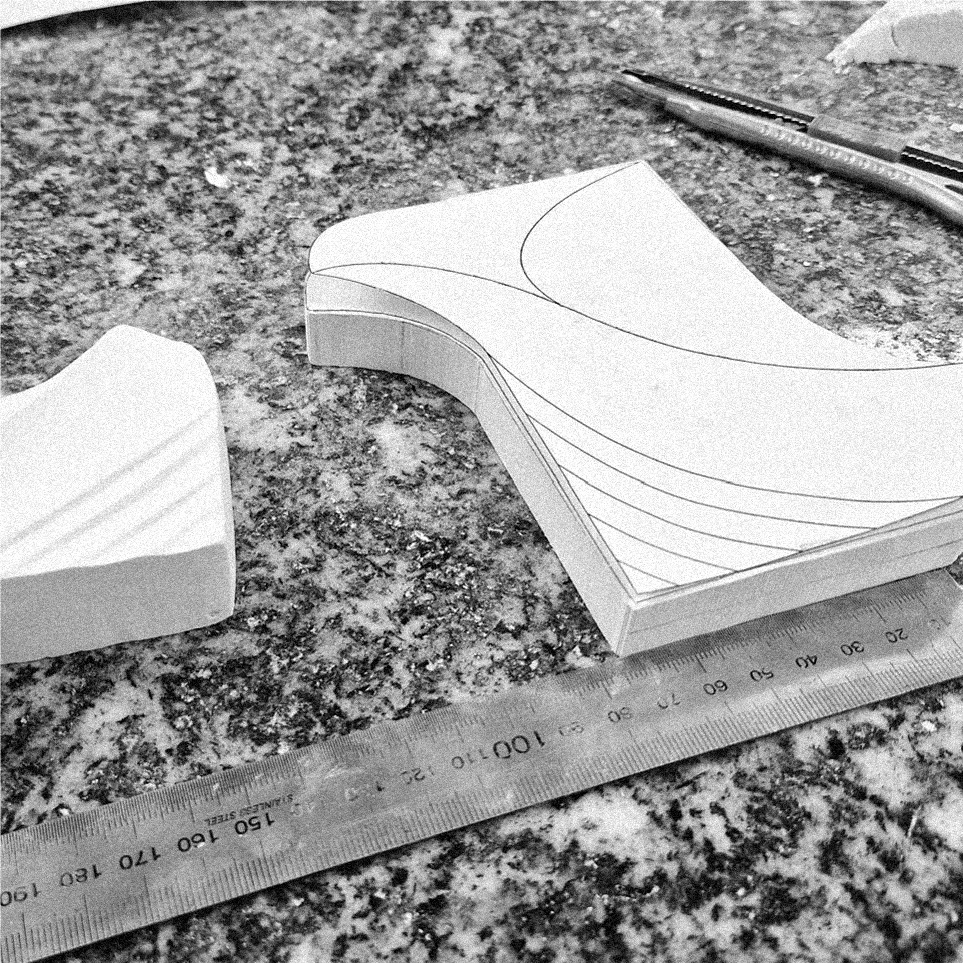

02 Plaster

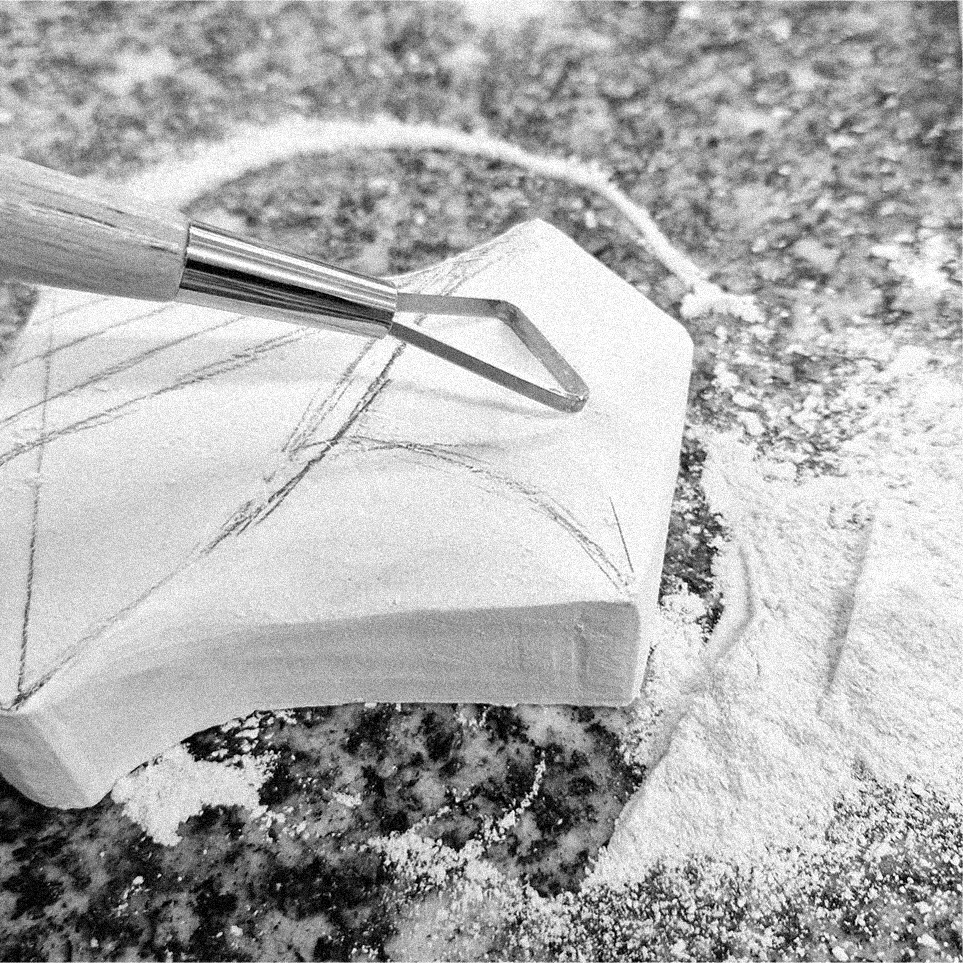

Initially, the swift sketches were translated into miniature plaster models. These models served as a tangible canvas for refining the geometry, relief, and overall spatial shape of the design.

Following the refinement process, a final plaster model embodying the perfected geometry was meticulously crafted. This model serves as the foundational blueprint for creating the subsequent casting mold.

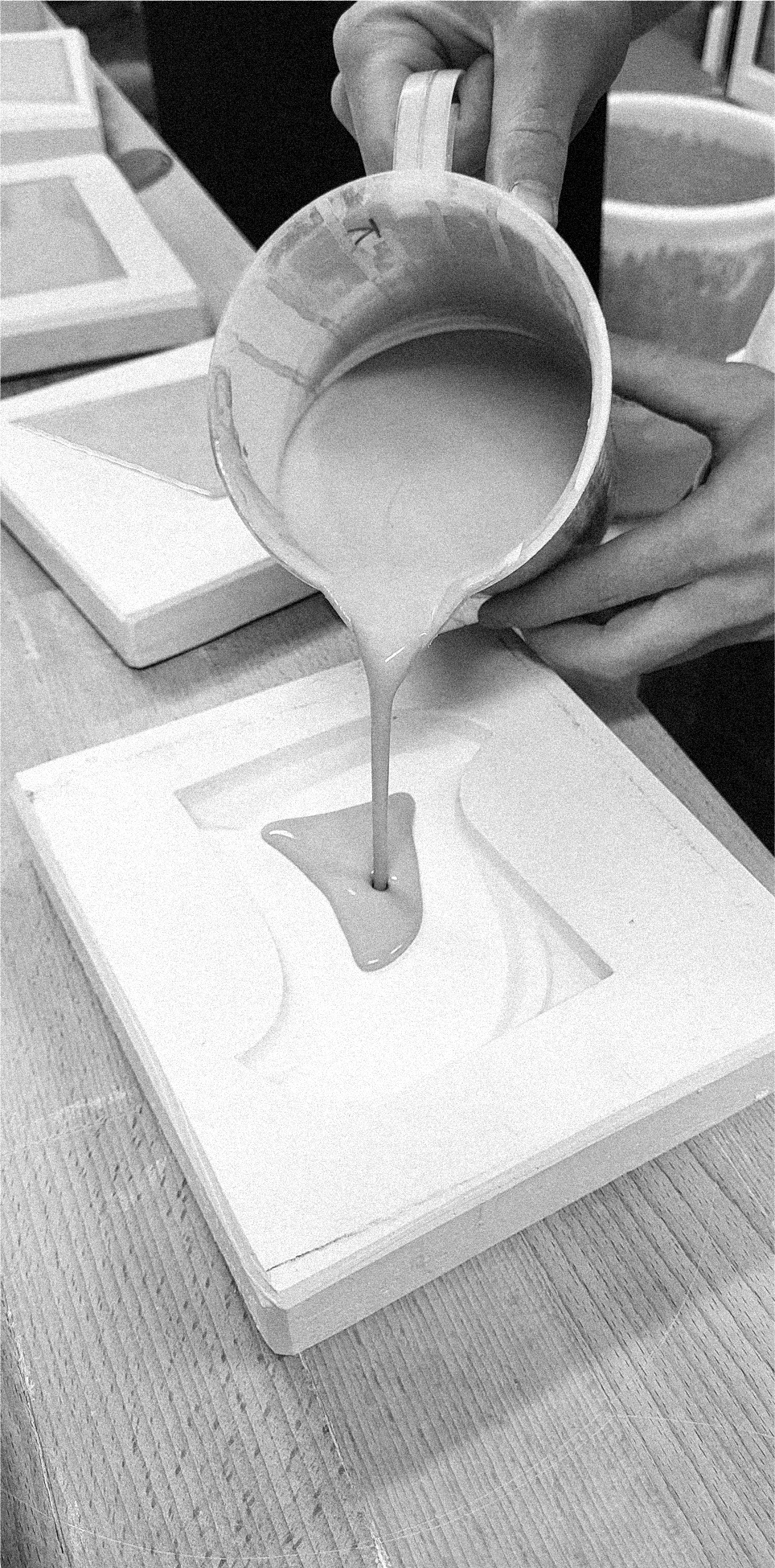

03 Casting

The ceramic mass is poured into the plaster mold, where it begins to take shape. After approximately 45 minutes of drying, the liquid ceramic solidifies into a cohesive body.

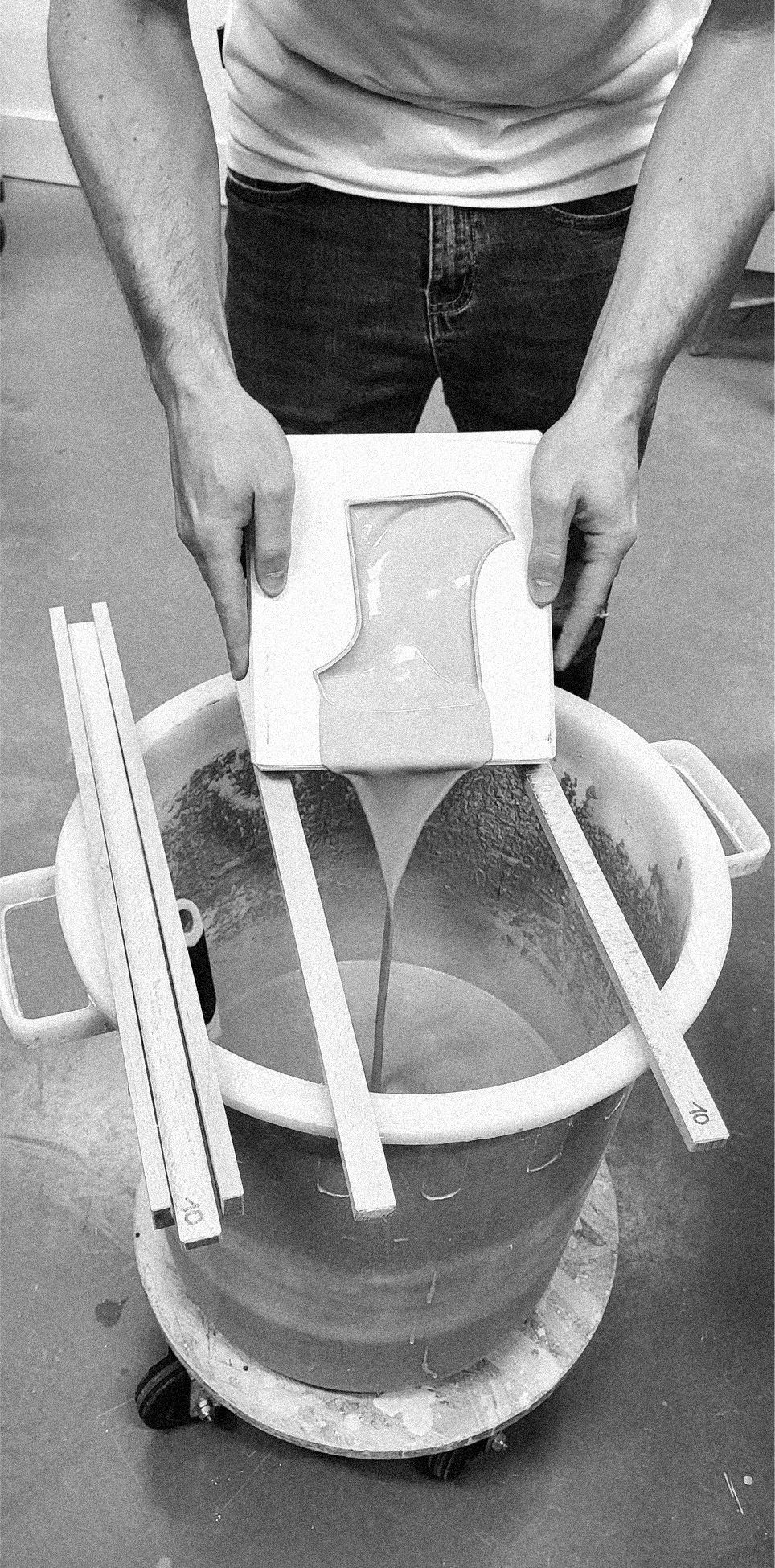

At this stage, any excess liquid ceramic is poured out, and the tile is left to dry further for another 45 minutes within the plaster mold.

At this stage, any excess liquid ceramic is poured out, and the tile is left to dry further for another 45 minutes within the plaster mold.

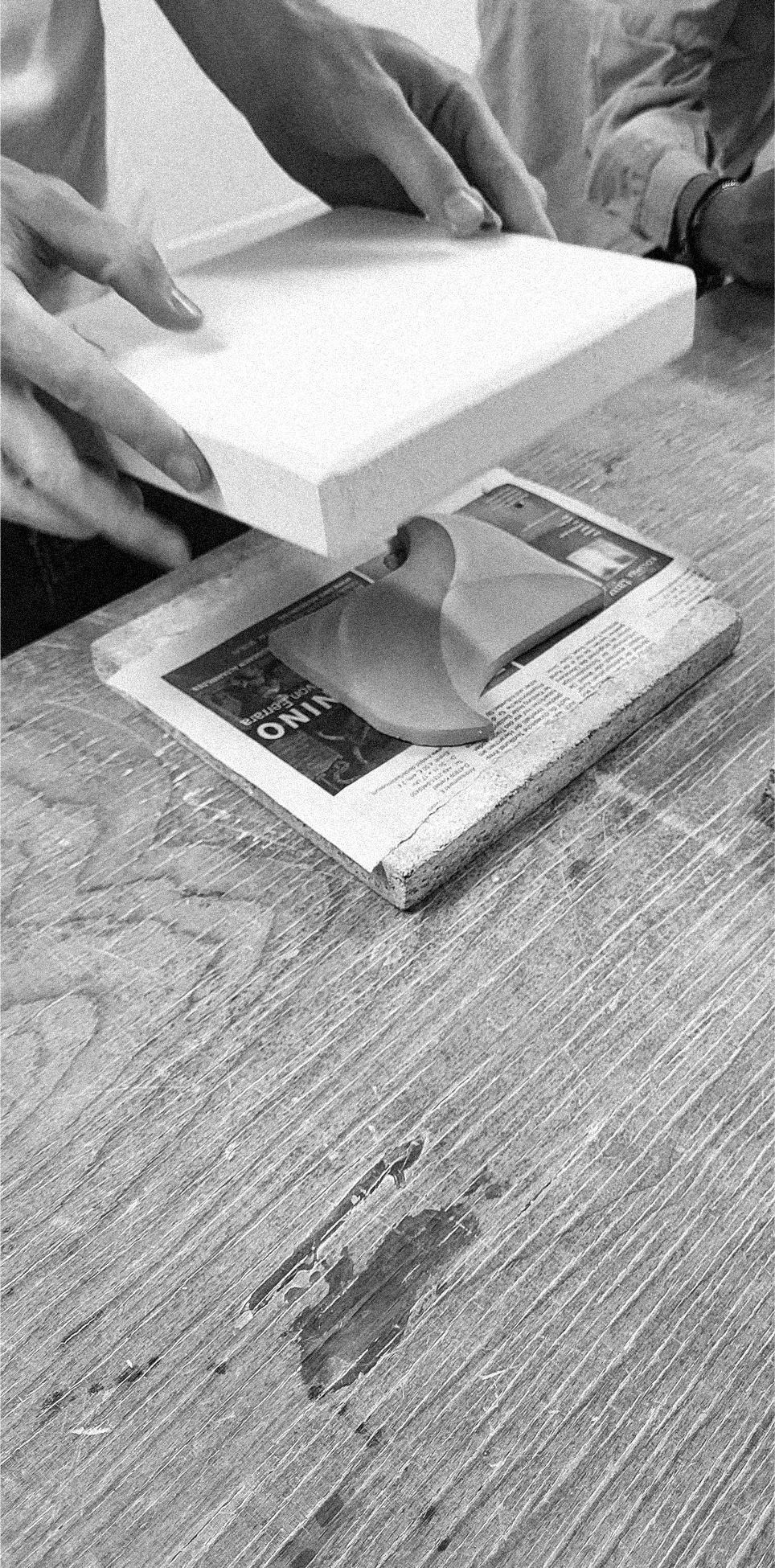

Once the tile has undergone the re-drying process, it is ready for demolding. After demolding and minor refinements, the tile enters a drying phase lasting 2-3 days.

Following this drying period, the ceramic undergoes its first firing, preparing it for glazing.

Following this drying period, the ceramic undergoes its first firing, preparing it for glazing.

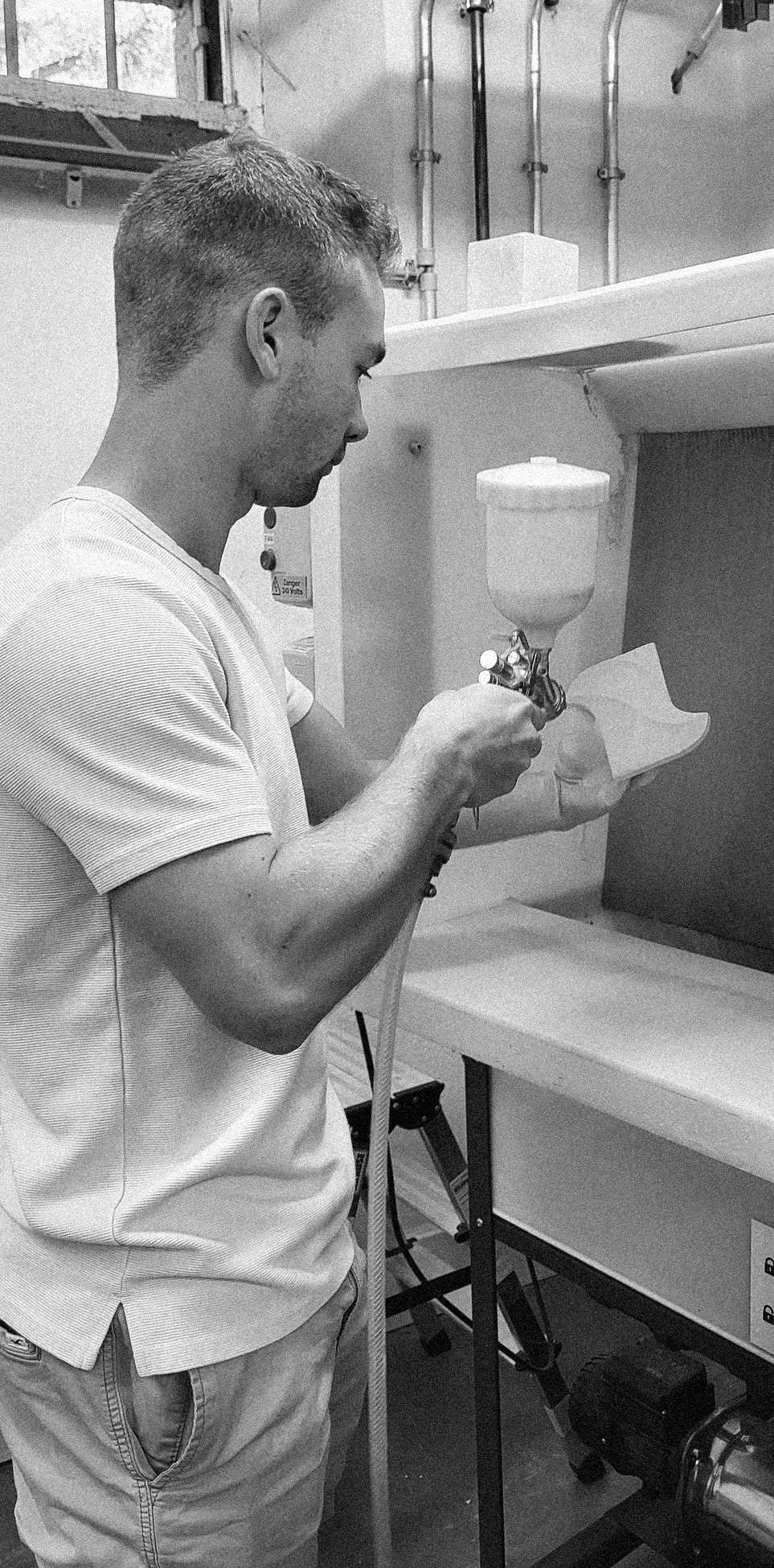

Once the glaze has been meticulously applied and any necessary minor finishing touches have been made, the ceramic tiles are ready for their second and final firing.

This firing process completes the transformation of the tiles, ensuring their durability and enhancing the vibrancy of the glaze.

This firing process completes the transformation of the tiles, ensuring their durability and enhancing the vibrancy of the glaze.